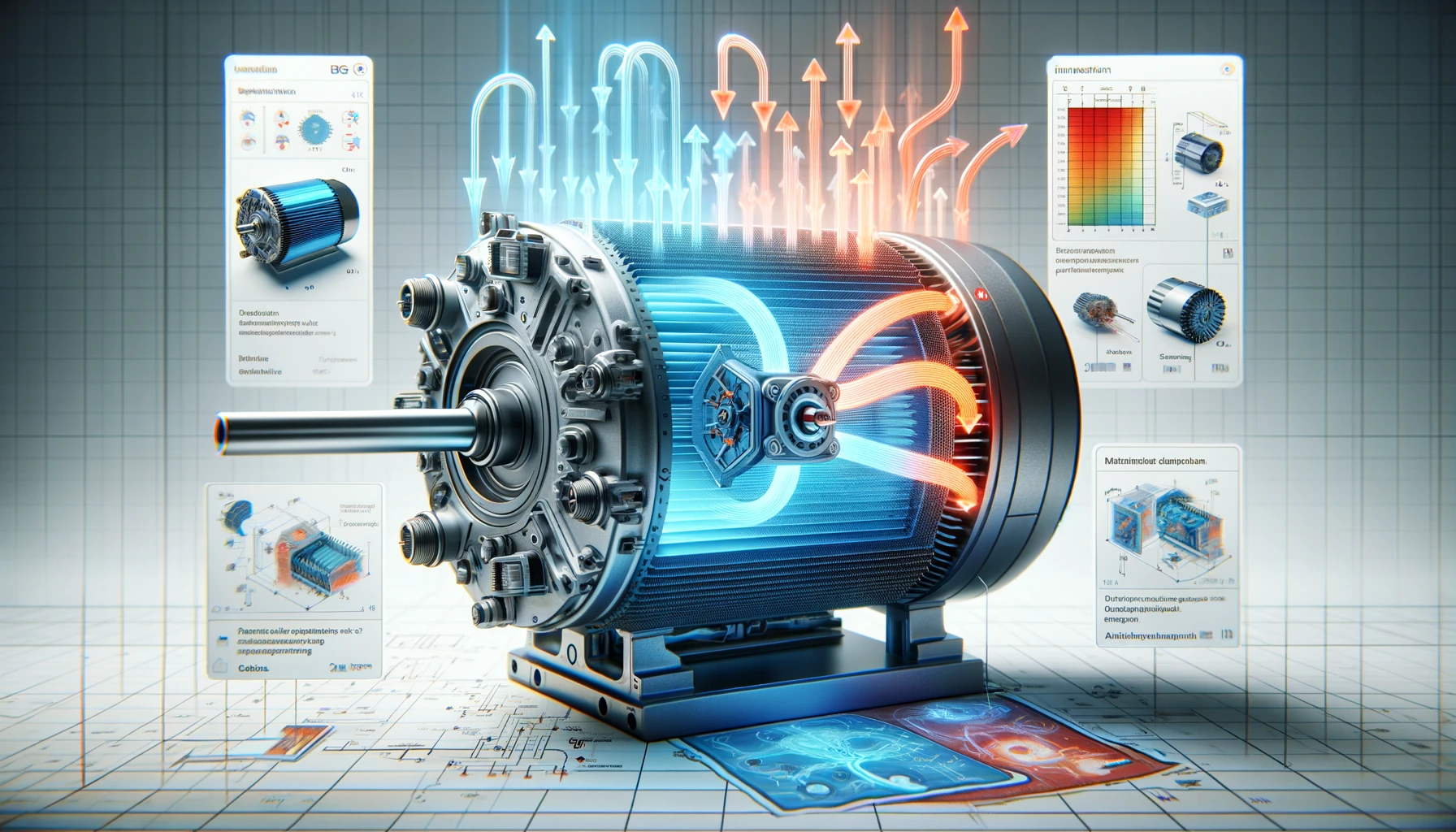

Design optimization of BLDC (Brushless DC) motors with a focus on enhanced heat dissipation is crucial for improving motor performance and longevity. BLDC motors are prone to heat generation during operation, which can degrade performance and reduce lifespan.

Advanced methodologies adopted by Experiqs engineers to model airflow and heat transfer within the motor, identifying areas of heat buildup and optimizing the motor’s design for better cooling efficiency. By analysing factors like geometry, materials, and cooling mechanisms, engineers can implement design modifications to ensure the motor operates within safe temperature limits, leading to improved efficiency and reliability.