Introduction

Data centers are the digital lifeline of our modern world, powering everything from cloud services and e-commerce to artificial intelligence and financial transactions. With the ever-growing dependence on 24/7 availability, reliability and efficiency are no longer optional—they are mission-critical.

However, maintaining such massive infrastructures poses significant challenges. Conventional maintenance strategies—reactive (fixing failures when they occur) and preventive (performing maintenance at fixed intervals regardless of condition)—are increasingly proving inefficient and costly.

This is where Machine Learning (ML)-based Predictive Maintenance comes into play. By leveraging data-driven insights, ML enables operators to predict equipment failures before they happen, minimize downtime, optimize maintenance schedules, and extend the lifespan of critical infrastructure.

Why Data Centers Need Predictive Maintenance

Data centers face unique challenges that make predictive maintenance essential:

- High Downtime Costs

According to the Uptime Institute, the cost of a data center outage is very high. Even a few minutes of downtime can disrupt mission-critical operations. - Energy Intensity

Cooling accounts for nearly 40% of total energy consumption. Suboptimal performance of HVAC or cooling systems drastically increases costs. - Component Complexity

Data centers consist of interdependent systems—servers, UPS units, CRAC/CRAH cooling, chillers, PDUs, and fire suppression systems. A small fault in one component can cascade into large-scale failures. - Preventive Maintenance Gaps

Scheduled maintenance is often wasteful: parts may be replaced too early, or failures may still occur between scheduled intervals.

Machine Learning-based predictive maintenance addresses these challenges by enabling condition-based, data-driven decision-making.

Role of Machine Learning in Predictive Maintenance

1. Data-Driven Failure Prediction

ML algorithms learn patterns from historical data and identify early signs of anomalies that may lead to equipment failure.

2. Anomaly Detection in Real Time

By continuously monitoring sensor data (temperature, vibration, power draw, fan speeds), ML models detect deviations from normal behavior.

3. Intelligent Maintenance Scheduling

Rather than fixed schedules, ML provides dynamic scheduling—servicing only when the probability of failure exceeds a threshold.

4. Root Cause Analysis

Advanced models not only flag risks but also correlate them to potential root causes, helping operators address underlying problems.

ML Workflow for Predictive Maintenance in Data Centers

A successful ML-based predictive maintenance system involves several steps:

1. Data Collection

- IoT Sensors: Measure temperature, humidity, vibration, current, airflow, and pressure.

- Logs & Events: Historical maintenance data, workload patterns, and incident records.

- Environmental Data: Weather conditions, power grid stability, seasonal impacts.

2. Data Preprocessing

- Filtering noisy sensor data.

- Handling missing values.

- Feature engineering (e.g., calculating rolling averages, thermal stress indexes).

3. Model Training

Different ML techniques can be applied:

- Supervised Learning: Classification models predict failure probability (e.g., logistic regression, random forests, gradient boosting).

- Unsupervised Learning: Anomaly detection using clustering or autoencoders.

- Deep Learning: Neural networks for complex time-series prediction.

4. Deployment and Monitoring

- Real-time inference on live sensor feeds.

- Continuous learning as new data arrives.

- Automated alerts integrated with facility management dashboards.

5. Decision Support

- Predictive insights for operations teams.

- Recommendations for part replacement, cooling optimization, or workload shifting.

Applications of ML-Based Predictive Maintenance in Data Centers

1. Cooling Systems (CRAC/CRAH, chillers, fans)

- ML predicts fan motor degradation or coolant leaks.

- Prevents overheating and eliminates hotspots.

- Optimizes energy usage by dynamically adjusting airflow.

2. Uninterruptible Power Supplies (UPS) and Batteries

- Monitors voltage, current, and temperature for anomalies.

- Forecasts battery degradation and replacement timelines.

- Prevents sudden power loss during grid instability.

3. Servers and IT Equipment

- Detects hardware stress (CPU overheating, abnormal power draw).

- Predicts failure of disks, network cards, or processors.

- Reduces downtime from unexpected server crashes.

4. Power Distribution Units (PDUs) and Switchgear

- Identifies overloading patterns or circuit wear.

- Prevents outages due to electrical faults.

5. Facility-Level Predictive Control

- Correlates workloads, environmental data, and infrastructure health.

- Balances loads across racks to prevent localized failures.

Benefits of Machine Learning-Based Predictive Maintenance

- Reduced Downtime

Anticipating failures before they occur ensures service continuity. - Cost Efficiency

Maintenance is performed only when necessary, avoiding unnecessary part replacements. - Energy Optimization

Intelligent cooling management reduces operational expenses. - Extended Equipment Lifespan

Preventing stress-related breakdowns increases component longevity. - Scalability

ML adapts to growing data centers, learning from new data streams. - Sustainability

Optimized energy consumption aligns with green initiatives and carbon reduction goals.

Case Example: ML in Cooling Optimization

A hyperscale data center implemented ML to monitor temperature sensors, fan speeds, and workload heat profiles. The ML system predicted fan failures days in advance by detecting abnormal vibration patterns. Additionally, it dynamically adjusted CRAC units based on server utilization.

Results:

- Cooling energy reduced by 15%.

- Avoided unplanned downtime from fan failures.

- Maintenance costs reduced by optimizing service intervals.

Challenges in Implementation

- Data Quality and Availability

Incomplete or noisy data reduces model accuracy. - Integration Complexity

Requires seamless integration with Building Management Systems (BMS) and DCIM platforms. - Model Interpretability

Black-box ML models can be difficult to explain to facility managers. - High Initial Investment

Deploying IoT sensors and ML platforms requires upfront costs. - Skill Gaps

Success requires expertise in both data science and data center operations.

Future Outlook

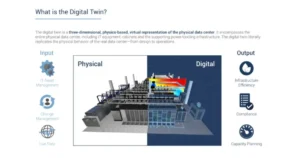

- Digital Twins: ML integrated with virtual replicas of data centers for real-time simulation and predictive control.

- Federated Learning: Sharing ML models across multiple data centers without exposing raw data, improving accuracy while maintaining data privacy.

- Autonomous Data Centers: Self-healing systems that automatically predict, diagnose, and resolve failures without human intervention.

- Sustainability Integration: Predictive maintenance models tied to carbon footprint monitoring and renewable energy usage optimization.

Conclusion

Machine Learning-based predictive maintenance represents a paradigm shift in data center management. By moving from reactive and preventive strategies to intelligent, condition-based interventions, operators can achieve higher uptime, lower costs, longer equipment lifespans, and improved sustainability.

As workloads grow and infrastructures scale, ML will be central to building the autonomous, resilient, and energy-efficient data centers of the future.