In the world of crude oil processing, one of the most persistent challenges lies not in the oil itself, but in the fine, often microscopic, water droplets stubbornly dispersed throughout it. These water-in-oil emulsions, though small in volume, can have outsized impacts on product quality, equipment efficiency, and overall refinery economics.

Removing these droplets is not just a matter of convenience—it’s a necessity. To meet strict product specifications and safeguard downstream operations such as distillation, cracking, or transport, the water content in crude oil must be reduced to extremely low levels, often well below 500 parts per million (ppm). However, traditional mechanical separation techniques often fall short of this target, especially when dealing with stable emulsions formed by naturally occurring surfactants in crude oil.

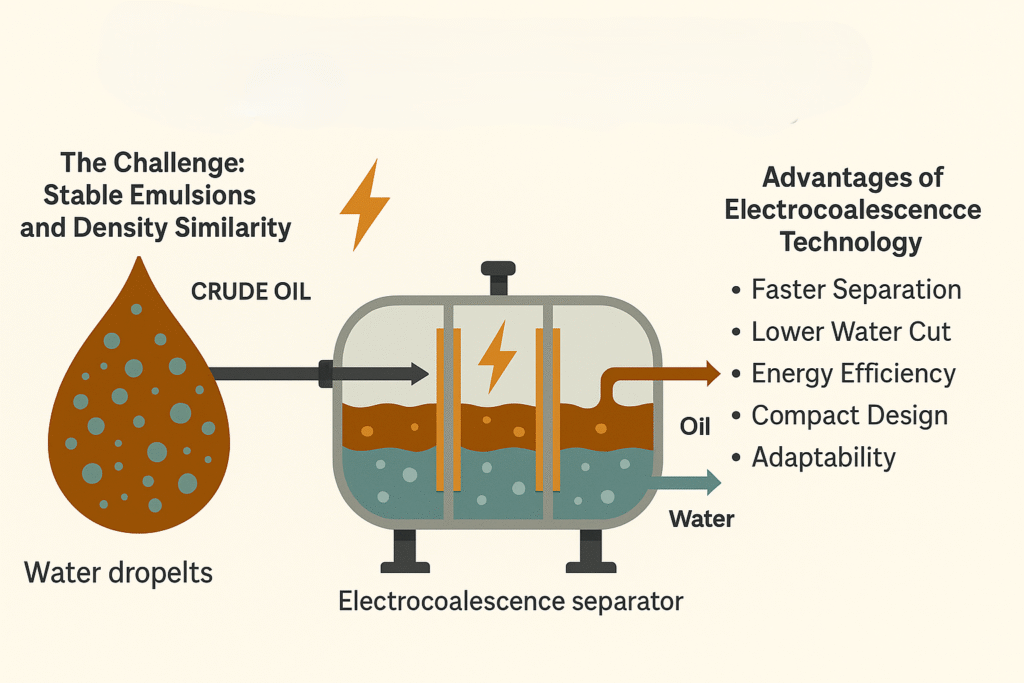

The Challenge: Stable Emulsions and Density Similarity

What makes these emulsions so difficult to break is a combination of physical and chemical factors. First, the water droplets are incredibly fine—often less than 10 microns in diameter. Second, the density difference between crude oil and water is relatively small, which limits the efficiency of gravity-based separation methods like settling tanks or hydrocyclones. Finally, the interfacial tension between oil and water is reduced due to the presence of natural emulsifiers such as asphaltenes and resins, which stabilize the emulsion and prevent coalescence.

These challenges mean that conventional methods, which rely solely on gravity or buoyancy-driven separation, are often too slow or insufficient for achieving the desired water content in a reasonable timeframe.

The Solution: Electrocoalescence

Electrocoalescence offers a promising solution to this long-standing issue. This technology applies a high-voltage electric field to the emulsion, leveraging electrical forces to enhance the coalescence of water droplets. When exposed to an electric field, the dispersed water droplets become polarized and begin to align with the field. As a result, adjacent droplets are attracted to each other due to dipole-dipole interactions and electrostatic forces, leading to collision and coalescence.

As droplets merge, they grow larger and heavier, accelerating their separation from the continuous oil phase. The effectiveness of electrocoalescence lies in its ability to disrupt the stabilizing film surrounding each water droplet—something that gravity alone cannot do effectively at small scales.

Advantages of Electrocoalescence Technology

- Faster Separation: Coalesced water droplets settle much faster, allowing for reduced residence time and smaller separator footprints.

- Lower Water Cut: Electrocoalescence can help achieve extremely low residual water concentrations (below 100 ppm), which is crucial for export specifications.

- Energy Efficiency: Compared to thermal or chemical methods, electrocoalescence typically consumes less energy and avoids additional chemical contamination.

- Compact Design: The equipment required for electrocoalescence is often more compact and easier to retrofit into existing facilities.

- Adaptability: It works effectively across a wide range of crude types and emulsion stabilities.

Implementation Considerations

While promising, the success of electrocoalescence depends on various design and operational factors:

- Electrode Configuration: The geometry and placement of electrodes significantly influence the uniformity of the electric field.

- Voltage and Frequency: The applied electric field must be carefully controlled—typically using AC fields in the range of several kilovolts—to avoid arcing or emulsion breakdown.

- Temperature and Viscosity: Higher temperatures generally improve separation efficiency by reducing oil viscosity and interfacial tension.

- Crude Composition: High asphaltene or resin content may require pretreatment or additional optimization of the electric field parameters.

The Future of Water-Oil Separation

As the oil industry continues to push for greater efficiency, reduced environmental impact, and improved product quality, technologies like electrocoalescence are becoming increasingly vital. Especially in offshore and space-constrained installations, where equipment footprint and processing speed are critical, electrocoalescence offers a high-tech, low-impact alternative to conventional dehydration methods.

Ultimately, integrating electrocoalescence into the crude oil processing chain represents a forward-looking step—combining physics, process engineering, and innovation to solve one of the industry’s most enduring separation challenges.