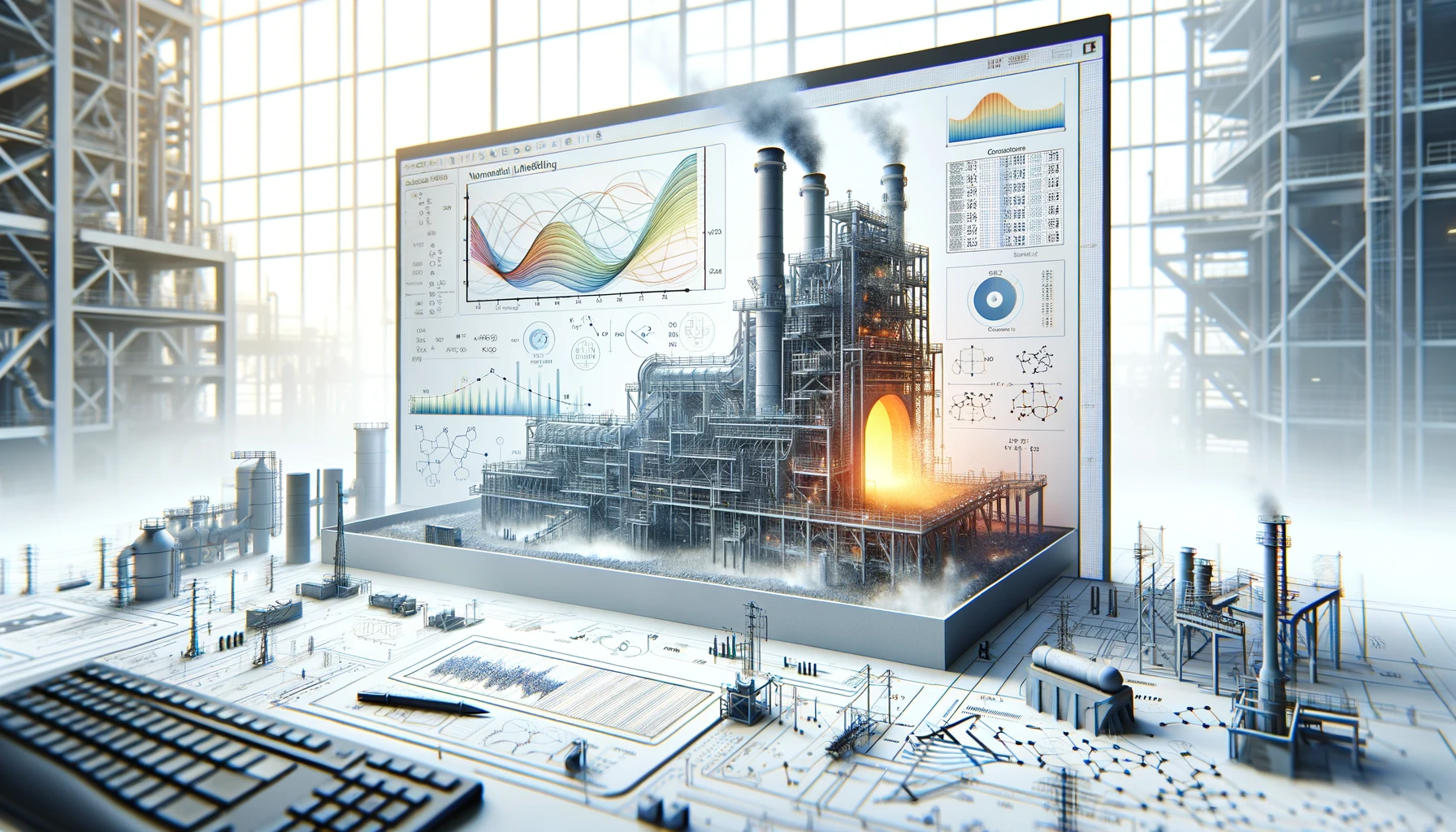

Hot molten metal flow in the hearth and taphole of a blast furnace is a critical aspect of the ironmaking process. Factors such as temperature, pressure, and slag composition influence flow behavior, requiring careful management to ensure furnace stability and productivity. At experiqs, we employ various techniques, including computational fluid dynamics simulations and physical modeling, to optimize the design of the hearth and taphole and predict molten metal flow dynamics.